Cannabinoid extraction using CO2 technology

Cannabinoid extraction methods using CO2 begins with the freezing of Cannabis resin glands (trichomes). This is to make them easy to loosen from foliage and to reserve the glands or trichomes’ potency levels. One of the unique things about the CO2 method is that other plant material such as leaves can be used in the process too.

Except for high initial costs for system purchasing and set up, the CO2 extraction method leaves no solvent residuals in the final product. A proper CO2 extraction setup is considered to be very important in order to achieve an efficient extraction process. Every Cannabis strain includes a different amount of Cannabinoids and therefore requires a different CO2 extraction program. Large CO2 scale extraction systems function under high pressure and have precision tolerance to get the most out of the separation process.

CO2 extraction technology is considered to be a controlled, robust, scalable and complies with GMP requirements and standards.

Two types of CO2 extraction methods are Supercritical Fluid and Dry Ice.

Supercritical CO2 extraction technology is characterized by a high diffusion rate which allows faster solids penetration than a liquid solvent. The naturally occurring carbon dioxide that is being evaporated spontaneously from the final product and residual solvents are not contained in the final product. In modern CO2 systems, the CO2 gas is recirculated and used in the following extraction cycles.

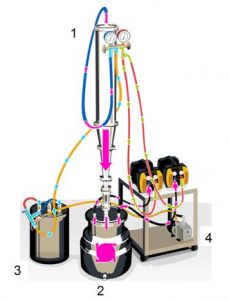

Supercritical CO2 system:

The process begins with placing milled cannabis, flowers, and leaves, into the extractor chamber. CO2 is applied from gas tank cylinders which flow into the extractor. A compressor is used in order to raise the pressure of the liquid CO2 and turn it into supercritical CO2. Supercritical CO2 physical state is both liquid and gas and therefore is able to extract the essential cannabinoids, trichomes, terpene oils, and waxes out of the plant material. The extracted substance is then passed to a separator. The heavy extract sinks to the bottom of the extractor while the supercritical CO2 is passed through a condenser back into the liquid phase. The liquid CO2 is then pumped to the storage tank where it can be reused.

CO2 extraction method Pros:

CO2 extraction method Cons:

Cannabinoid extraction using Butane (BHO) Technology

Butane extraction technology is considered to be relatively inexpensive, easy to find, and very efficient.

Butane extraction technology leaves heavy metal residues in the extracted resin.

Butane extraction technology is considered hazardous, especially if being used in non-industrial facilities and forbidden to be used in several states such as California. In order to use the BHO extraction technology, an explosion-proof facility and equipment must be used.

Butane is very flammable and highly explosive with a boiling point of 0.5oC and a flash point of 60oC.

The Butane extraction method is considered non-GMP due to health risks associated with the solvent residuals, which may be present in the final product.

BHO system:

The process begins by placing milled material into the butane extraction tube. Butane, which is applied from gas tank cylinders is sprayed into the extractor chamber. The cannabinoids, trichomes and terpene oils and waxes then drop out of the plant material to the bottom of the extractor. The bottom of this double boiler chamber is filled with water and is heated in order to evaporate the butane. A vacuum pump is used in order to evaporate the remaining butane.

Butane extraction method Pros:

Butane extraction method Cons:

Additionally, the CO2 extraction method is a better extraction method for terpene extraction in cardamom (Beta-pine, Cineole, Linalool, and alpha-terpinol).

Using Propane at high pressure will enable an increase in the yield of the CO2 extraction process.

Butane is a very strong solvent for extraction and can easily be incubated with the Cannabis plant material for too long, it can continue to pull out more and more polar compounds like chlorophyll. With some fine-tuning of the CO2 extraction process, it can be avoided and eliminated in case process parameters were validated.

Rapid extractions are possible with butane but little control of the material is present, while CO2 can be tunable and therefore is able to collect all of the same material, just through a segmented process.

About Cannabis GxP consultancy

Cannabis GXP is proud to stand at the forefront of the Cannabis industry in Israel and worldwide thanks to many years of experience in these areas.

Our team is compelled to spread the message of the importance of cannabis science, regulation and standardization as the world enters a new era of cannabis legislation.

We aim to position our clients with their best foot forward when it comes to anything and everything cannabis related.

Our vast expertise allows us to assist companies in a wide range of services and needs: Anything from Cannabis R&D, growing and manufacturing, new products development, facility design, technology, Quality Assurance, Good Practices (GAP/GMP/GLP/GDP/GCP), staff training, local and global regulations.

Cannabis GxP is a subsidiary company of Bio-Chem Ltd. (2007), a consultancy firm for the Pharmaceutical field, medical devices, Cosmetics and food supplements industry based in Israel.

Our cannabis consultancy services include:

If you need one or several of our services concerning advice for choosing the best extraction technologie for you, we will be more than happy to assist.

Please do not hesitate to contact us for further information.