The current global status of Hemp

It is without question that the cannabis industry in general, especially cannabidiol (CBD), is headed toward becoming one of the larger new industries in the modern world. An increased interest in the plant and its CBD content accompanied by new regulatory standards such as GACP and GMP is happening across the globe and is growing exponentially.

In 2018, Hemp was removed as a controlled substance in the U.S. They made it legal and began to regulate the production of Hemp (‘Farm Bill’). The regulation of Hemp products is more flexible in Europe and other countries around the world, allowing companies to take part in this industry as new or as existing players. Unlike regular cannabis plants, Hemp is mostly cultivated outdoors and in uncontrolled conditions. In order to take part in the future Hemp industry that is certain to become more medically oriented and accordingly monitored, there is a significant regulatory gap to fill.

Hemp based products

As we have witnessed throughout history, hemp can be cultivated for different purposes. Industrially, mainly for the fiber and the seeds, medically for its CBD content and therapeutic potential and also recreationally. High CBD strains, now legal in most of Europe, are smoked, vaped or used as CBD flowers for its soothing properties. They are enjoyed for their pleasant taste and aroma thanks to wide terpene profiles and advanced cultivation techniques.

Hemp CBD buds and products, just like other cannabis-based products, should meet all safety and quality criteria such as CBD content, microbial level, heavy metals, residual solvents, and pesticides. Therefore they should all be controlled and tested, through the entire process, from seed to shelf.

Hydroponic cultivation technology for Hemp

Hydroponic growing systems have been used in traditional agriculture such as growing lettuce for many years. In the cannabis world, the Hydroponic technique is more common in cannabis plant growing and less for Hemp. As of now, there are very few examples of CBD strains cultivation using the hydroponic system in the world. There is no real difference in cultivating high CBD strains than cultivating other strains.

The hydroponic method of growing originated with recreational cannabis and was primarily used to increase the THC level in the plant and give the flowers a better appearance. The purpose was to create a stronger plant in order to be smoked or have its contents extracted.

Now that widespread interest has slowly shifted from THC to CBD, the same type of methods can be applied to high CBD strains. Increasing this time, the CBD content for the flower can be directly consumed after harvest. Whether it is for its THC or its CBD content, the plants are grown hydroponically the same way. The main purpose of Hydroponic cultivation with cannabis is to create nice looking and good smelling buds. The chemical content of the flowers will depend on the strain and the way it is grown.

There are different ways and different tools to do this, but basically, a hydroponic cannabis growing system will use water and supplements as a growing medium. The roots, instead of growing in the earth, grow directly in water or on an inert substrate. The list below shows the main elements that are needed in a Hydroponic facility and the basic guidelines for growing CBD strains or THC strains hydroponically.

The advantages of Hydroponic cannabis cultivation

Industrial hemp and cannabis farmers can easily increase production and resources and employ efficiency just by introducing a hydroponic system into their facilities.

Cannabis Hydroponic basics

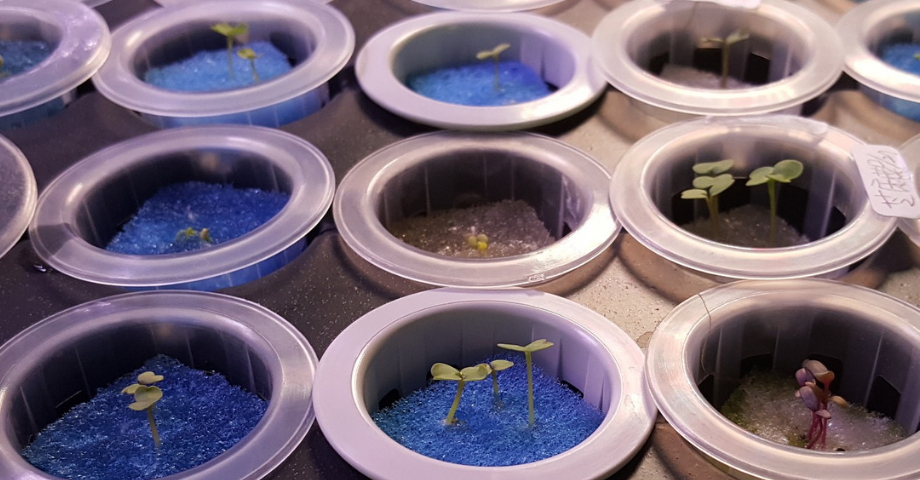

- Growing container – for plant root development

The container is the part of the system that holds the plant while the roots bath in a media flooded, streamed, or dripped with nutrients.

- Sump tank – for nutrients supply

Mostly accompanied by a mixing tank the sump tank is most commonly used on a commercial scale. The Sump tank holds and mixes the nutrients solution.

- Pump – for irrigation

The role of the pump is to bring the water from the sump tank to the media where the plant is.

The power of the pump needed will obviously depend on the size of the operation.

Types of hydroponic system designs

There are many different possible designs for a hydroponic cannabis farm, but we will mention the main ones and the most popular ones for growing cannabis.

- Deep Water Culture (DWC)

DWC design uses a raft which holds the plants over a solution tank. The nutrient solution runs from the sump to the tanks slowly to deliver nutrients without troubling the fragile roots. It is not easy to adapt the traditional DWC systems to large facilities. Once the DWC is installed it becomes a fixed system and becomes easily handled if needed.

- Nutrient Film Technique (NFT)

This is the most common technique used with any type of plant in greenhouses or on a large scale. This design uses a series of narrow troughs or gutters where the nutrient solution is simply running down the length of the gutter in a thin film. This technique is ideal for horizontal facilities but is not very space efficient and not the best for big root plants such as cannabis. This method is also less secure because if the water circulation has problems in the pumps or energy supply for any reason, the nutrient solution flow stops and plants can be severely damaged.

-

Vertical/Zip grow

This technique is more relevant for indoor cannabis hydroponic cultivation, requiring artificial lightning and so not recommended for outdoor. The vertical/zip grow technology uses vertical spaces rather than a single horizontal design. This technique is getting more and more attention especially because of its space-efficient technique. However, it is less adaptable to the cannabis plant since smaller plants become shadowed by higher plants. Lastly, more labor is required for this type of design.

- Media Base

This method is the simplest one and the most common for a large-statured plant like cannabis. A media-based system uses aggregate or fiber media in a container, most commonly in Media beds or Bato buckets.

- Mix hydroponics systems

New hydroponic technologies combine the main benefits of each system and reduce the possible inconveniences. Plants are characterized as having high plant density, great root development and easy access to water, nutrients, and air. This allows easy labor to increase the yields while minimizing costs.

About Cannabis GxP consultancy

Cannabis GXP is proud to stand at the forefront of the Cannabis industry in Israel and worldwide thanks to many years of experience in these areas.

Our team is compelled to spread the message of the importance of cannabis science, regulation and standardization as the world enters a new era of cannabis legislation.

We aim to position our clients with their best foot forward when it comes to anything and everything cannabis related.

Our vast expertise allows us to assist companies in a wide range of services and needs: Anything from Cannabis R&D, growing and manufacturing, new products development, facility design, technology, Quality Assurance, Good Practices (GAP/GMP/GLP/GDP/GCP), staff training, local and global regulations.

Cannabis GxP is a subsidiary company of Bio-Chem Ltd. (2007), a consultancy firm for the Pharmaceutical field, Medical devices, Cosmetics and food supplements industry based in Israel.

Our cannabis consultancy services include:

We understand that the different techniques and possibilities can be confusing, we would be happy to help you choose the Hydroponic technology best suited to your company’s needs. Whether you are working with CBD or any other cannabis compounds please do not hesitate to contact us.