Choosing the proper extraction technology for pharmaceutical grade cannabis is one of the most important issues in the design of any cannabis manufacturing facility.

Before we start comparing extraction processes, we must look at the entire production flow, and ask the appropriate questions.

- What are the final products that we plan to produce; tablets for oral use, API’s, cosmetics, etc.

- What is the chemical profile of the plants to be extracted?

- Are there any regulatory limitations; solvent usage, environmental hazards?

- What are the prices of the final products going to be a few years down the road?

Once those questions are answered, we can start evaluating the right technology to use.

Which cannabinoids extraction technology should be chosen?

There are many technologies available on the market for the extraction and isolation of specific cannabinoids. Extraction technologies that fit large scale production can be divided into 3 main categories:

- Classic Solvent extraction – using common organic solvents such as ethanol, hexane, or pentane.

- Gaseous extraction – using materials that remain in their gaseous state at room temperature – butane, photonic extraction, dimethyl ether

- Supercritical extraction – involving CO2, Propane and other chemicals.

All of these technologies have their ups and downs, and all require fine-tuning in order to achieve the desired end product. Some are better for cannabinoid acid production, and some have better terpene profiling of the products. Once the cannabis has been extracted, the next step is often the purification of the extract.

What to consider when choosing the best extraction technology?

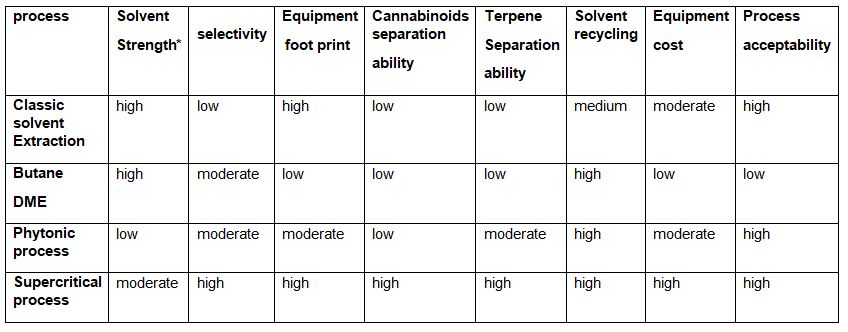

To evaluate the technologies, we have marked their performance in the following fields:

- Solvent strength – how much solvent is used to extract the desired products.

- Selectivity – how much undesired product will the solvent carry to the extract (most of this waste will have to be cleaned later)

- Equipment footprint – the size and volume of the equipment for a given load to be extracted at a given time.

- Cannabinoid separating ability – the ability of the process to define a single or a group of Cannabinoids at a reasonable time and yield.

- Terpene separation – the ability to separate other molecules of pharmaceutical interest.

- Solvent recycling – recovering the solvent for another extract, based on ease of recycling while minimizing carryover.

- Equipment cost – the price of purchase (including minimum refining)

- Process acceptability – the amount of knowledge on the pharmaceutical aspects of the process.

Comparison between different cannabinoids extraction technologies

About Cannabis GxP consultancy

Cannabis GXP is proud to stand at the forefront of the Cannabis industry in Israel and worldwide thanks to many years of experience in these areas.

Our team is compelled to spread the message of the importance of cannabis science, regulation and standardization as the world enters a new era of cannabis legislation.

We aim to position our clients with their best foot forward when it comes to anything and everything cannabis related.

Our vast expertise allows us to assist companies in a wide range of services and needs: Anything from Cannabis R&D, growing and manufacturing, new products development, facility design, technology, Quality Assurance, Good Practices (GAP/GMP/GLP/GDP/GCP), staff training, local and global regulations.

Cannabis GxP is a subsidiary company of Bio-Chem Ltd. (2007), a consultancy firm for the Pharmaceutical field, medical devices, Cosmetics and food supplements industry based in Israel.

Our cannabis consultancy services include:

If you need assistance in finding the best extraction technology for pharmaceutical cannabis that suits you, we will be more than happy to assist.

Please do not hesitate to contact us for further information.